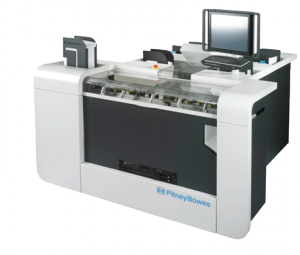

Pitney Bowes: DI6100 – Combining flexibility and productivity with the best technology

Combining flexibility and productivity with the best technology

Since their introduction the DI range of production inserters has handled over 5 billion items of mail around the world. The DI6080 and DI6100 are the latest versions and bring innovations to the range without sacrificing its well deserved reputation for durability and flexibility. They are the ideal choice for

production environments of all types.

Improvements at a glance

• New stepper motors to increase folding capacity and improve the quality of every fold

• New graphical user interface on 17 inch screen guides the user through set up and helps resolve problems

• Increased feeder capacity for better productivity

• Upgraded server computer with dual hard drive and network connections produces output files more quickly

Flexibility – the all purpose inserter

• Whatever you need to run, the DI6080/ DI6100 can handle it. Insert into different sized envelopes in the same job, including C4 when fitted with the optional C4 insertion table

• Any insert or sheet feeder can be the control feeder. This allows any feeder to carry the addressed document so you can set up the DI6080 or 6100 how you want to. The operator only loads the feeders that are needed; reducing set up time spent emptying feeders from the previous job.

• Fits into your existing set up. A compact 2m x 2m footprint means you can fit a lot of inserter into a relatively small space.

• A range of input options. The DI6080 and 6100 can handle sheets in continuous or cut sheet formats, and insert them into C5 or DL envelopes. No matter how the documents come to you, the DI6080 and 6100 will deal with them

• Increase every operator’s productivity. The DI6080 and 6100 have an ergonomically efficient layout so the operator spends less time walking around the machine to set up jobs or keep them running.

• Control each operator’s access. Log in facility means that you can precisely set up jobs for each operator, reducing the chance of errors.

Integrity – know what’s been mailed

• Demonstrate that each recipient receives the correct mailing. With a scanner on any or all feeders and on envelope output, you can match across all feeders and generate an output file for every job to track what happens to each mail piece. The output file also makes it easy to reproduce any mail pieces that are incorrect or missing.

• Supports a wide variety of control marks. The DI6080/6100 can handle all common scanning technologies such as OMR, OCR, BCR, Datamatrix etc.

Typical uses for a DI6080 / 6100

Credit Card statements

Utility bills

Insurance statements

Central or local government invoices and statements

Processing re-prints from high volume mail runs

As an additional up system to handle larger volume runs once or twice a month

Who could benefit from a DI6080 / 6100?

Banks

Utility Companies

Financial Institutions

Direct mail / document service bureaus

Insurance Companies

Central and local government departments

Specification

| Physical dimensions | |

| Length | 1700mm |

| Depth | 1820mm |

| Weight | 550kg |

| Configuration | 2 sheet feeders and 4 insert feeders |

| Speed | Up to 10,000 envelopes/hour 2,500 C4 envelopes/hour (optional) |

| Numbers of programmed jobs | Unlimited |

| Insertion capability | up to 8mm in C4 envelopes |

| Electrical | 230 volts, 14A max |

| Noise level | 76 dBA |

Material sizes

| A4 feeder | min | max |

| Document length | 210mm | 215mm |

| Document width | 150mm | 356mm (14’’) |

| Paper weight | 75gsm | 130gsm |

| Load capacity | 1000 documents (option 4000) |

| Insert feeder | min | max |

| Document length | 180mm | 215mm |

| Document width | 70mm | 150mm |

| Paper weight | 80gsm | 350gsm |

| Load capacity | 1500 inserts |

| Envelope feeder | min | max |

| Envelope length | 210mm | 242mm |

| Envelope width | 110mm | 162mm |

| Flap height | 35mm | 45mm |

| Paper weight | 80gsm | 110gsm |

| Load capacity | 1000 envelopes |

Optional C4 module feeder

Inserts up to 60 A5 sheets into C4 pocket envelopes

| Pocket Envelopes | min | max |

| Pocket length | 310mm | 329mm |

| Pocket width | 229mm | 241mm |

| Flap height | 40mm | 50mm |

| Paper weight | 80gsm | 120gsm |

| Load capacity | 250 pocket envelopes |